What is H-UV Technology? - The new generation of litho printing

What are the problems with traditional litho print?

1. Dull imagery on uncoated papers

2. Drying Problems

3. Marking

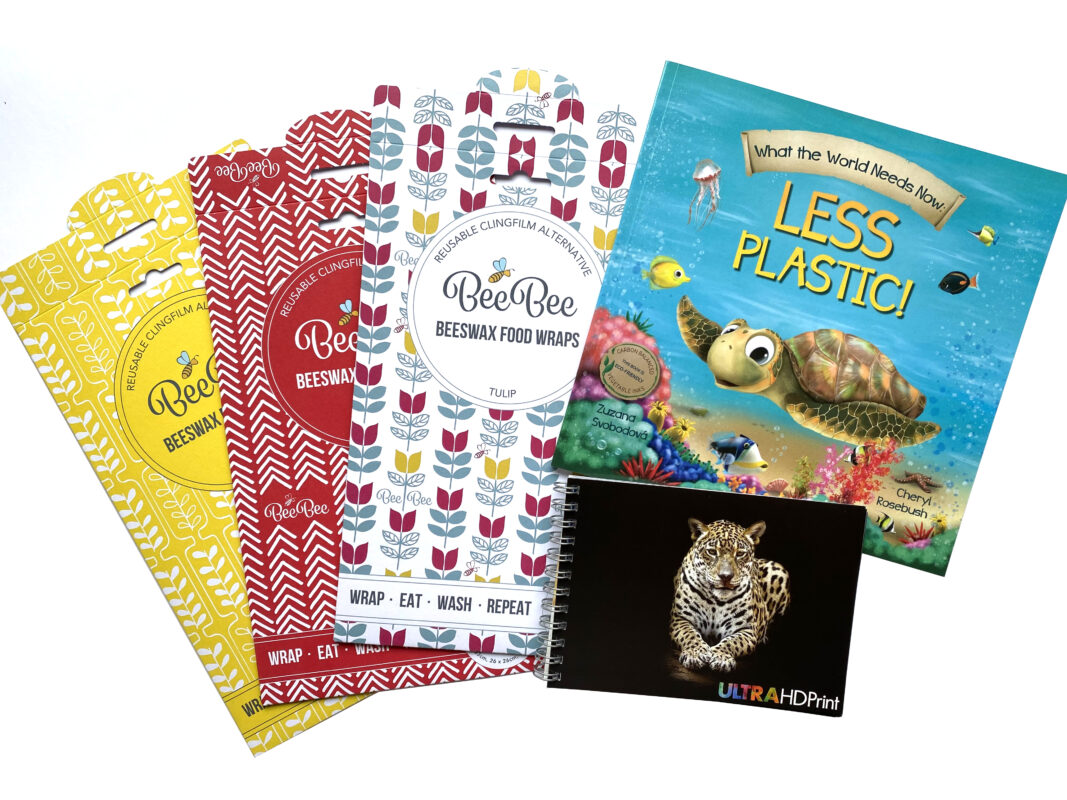

Dull imagery on uncoated Paper – Finally! The endless years of dull flat images lacking detail and definition on uncoated papers, recycled papers and open carton board are now over. H-UV prints on top of the material and dries instantly. This gives a crystal clear image which we call Ultra HD Print.

Drying Problems

Have you ever noticed that your traditional litho print has rubbed or is delivered still wet and prone to rubbing? Have you ever been told the ink has not dried because of the material it’s printed on? Do you have to pay for a coating to prevent this or is your printer coating without you knowing? Well we can guarantee you will not have any of these problems with Barnwell Print. Ultra HD Print eliminates rub, any drying problems and does not require coating, simple.

Marking – This comes from having to print both sides of the sheet, when passing back through on the second side, the still wet ink is prone to marking your sheet. Ultra HD Print enables the ink to be dried via a UV light source which instantly cures the ink to ensure no marking can occur, the ink is dry before it even lands in the delivery, meaning 100% mark free print on every sheet.

What is the downside of H-UV?

None! We are not joking you will see nothing but improvements to the print quality.

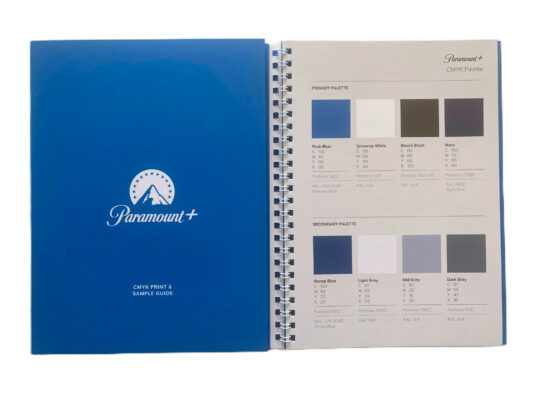

Our H-UV Press in Production

What are the upsides of H-UV Technology?

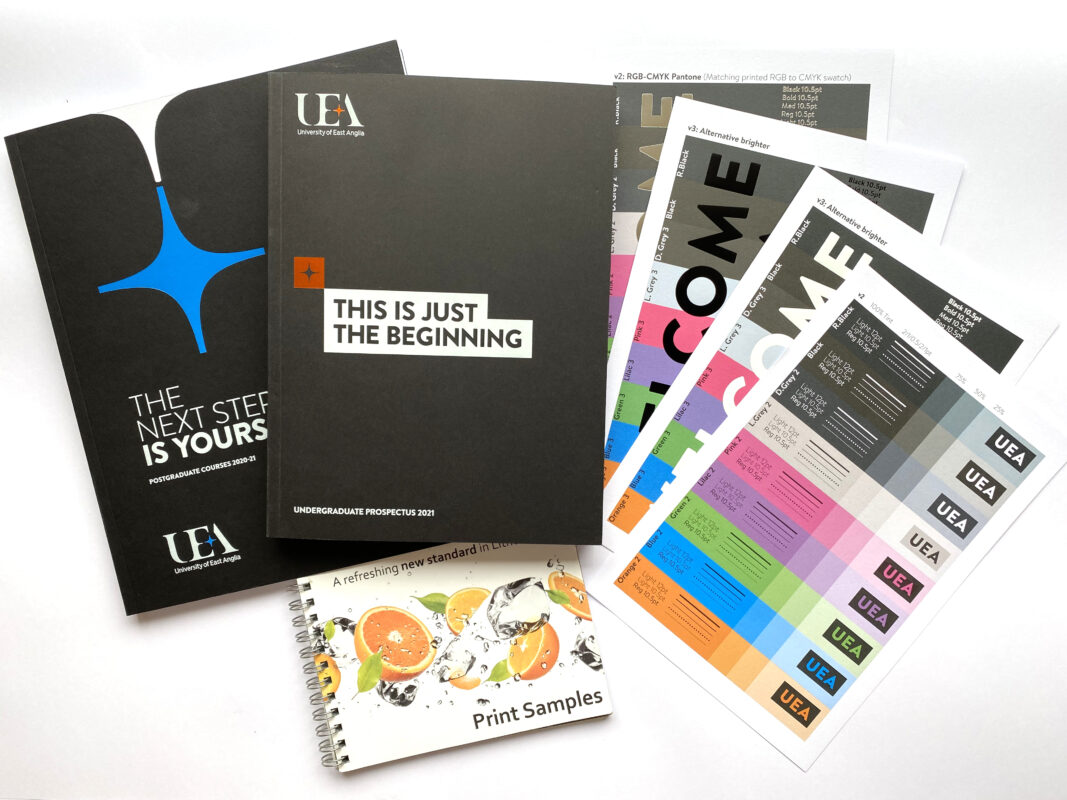

Massively Improved print quality on all uncoated materials.

Print with more punch and depth of colour on coated material.

No rubbing, no marking and no complaints.

Quick turn around times if required.

Very High gloss coatings.

Improved opacity with reduced show through than conventional litho printing.

More energy efficient which helps to reduce our carbon foot print.

H-UV — Innovative UV Curing System

The Komori H-UV System is an innovative UV curing system that uses a UV lamp developed with Komori know-how and high-sensitivity UV ink. With just one lamp mounted in the delivery, this system offers high print quality and reliability as well as excellent economic and eco-friendly performance.

Marking

This comes from having to print both sides of the sheet, when passing back through on the second side, the still wet ink is prone to marking your sheet. Ultra HD Print enables the ink to be dried via a UV light source which instantly cures the ink to ensure no marking can occur, the ink is dry before it even lands in the delivery, meaning 100% mark free print on every sheet.

Shorter Total Turnaround Time

Extremely effective in shortening the time from receipt of materials to delivery.

Improved Quality due to Powderless Operation

None of the troubles associated with the scattering of powder granules and much easier post-press.

Elimination of the Dry-Down

Simple color determination, so printing with client in attendance and production printing are easier

Environmentally Friendly – The H-UV system contributes tremendously

to a better environment inside the printing plant because it does not discharge ozone, does not use powder and is nearly odorless.

Effective Space Utilization

Since the H-UV system is compact, installation space is minimal and no area is needed to place printed items that have not yet dried.